A tanker had loaded cargo and the crew was preparing to depart. The pilot was on board and the gangway (8 meters long and weighing 250kg) was to be secured for sea. It was hooked on to the deck crane, which had a safe working load (SWL) of 5,000kg, and lifted away from the ship’s side, then brought slowly down to the stowed position. Just before the gangway was in the stowed position the topping cylinder broke away from the crane jib and the crane arm gave way. The gangway fell on to the deck, but as all crew had been standing clear there were no injuries and the gangway was only slightly damaged.

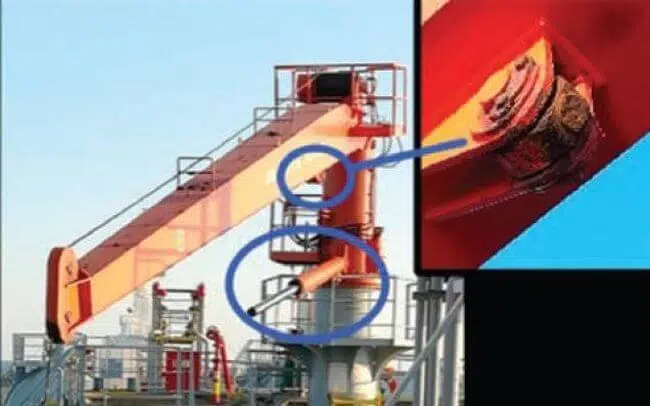

The company investigation found that the hydraulic cylinder eye attachment fitting had not been properly maintained. The fitting was

situated in a relatively inaccessible part of the crane and greasing of this part had been neglected.

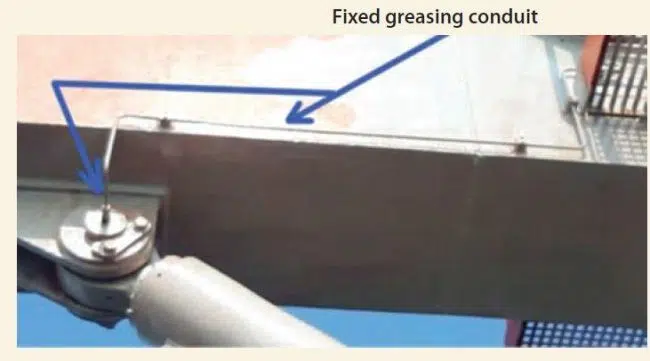

In response to this accident, the greasing point of the cylinder eye attachment has been fitted with a fixed conduit so the operator can perform greasing directly from the safety of a nearby platform, as seen in the picture

Additionally, the job card was updated. Instead of a generic maintenance description, the new card indicates specific greasing

points to help the crew to identify all maintenance areas. Finally, the manufacturer reviewed the design of cylinder eye bushings. Subsequent cranes will have bushings made of synthetic material instead of metal to reduce the risk of the steel pin seizing.

Lessons learned

- If lifting equipment is not well maintained even a relatively small weight in relation to the crane’s SWL can cause a failure. In this case, the lift was only 5% of the crane’s capacity.

- Equipment maintenance job cards should be as specific as possible to help crew identify all areas of work that need to be covered.

Cart is empty

Cart is empty